How Industrial Design and Machine Design are Shaping the Future of Manufacturing

12 November 2024

Introduction: Industrial design and machine design are evolving rapidly to meet the demands of modern manufacturing. With the help of new technologies like AI, 3D printing, and simulation, these fields are driving innovation across industries. Let’s explore how these advancements are shaping the future of manufacturing.

Main Points:

Automation and Robotics in Machine Design

Machine design increasingly incorporates automation to optimize efficiency and reduce manual labor.

Robots and AI-powered machinery are allowing for faster, more precise manufacturing processes.

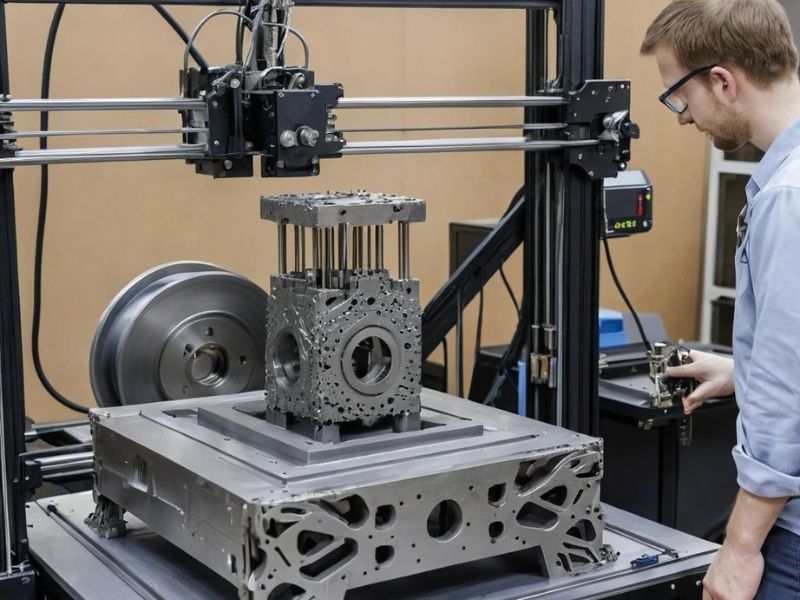

3D Printing and Customization in Industrial Design

3D printing is enabling high levels of customization and personalization in products, which appeals to modern consumers.

With lower costs for small production runs, companies can create custom parts and products quickly.

Sustainable Design Practices

Sustainable manufacturing is becoming a top priority, with industrial designers focusing on minimizing waste and energy use.

Machine designers are creating more energy-efficient equipment and exploring recyclable and biodegradable materials.

Digital Twins and Virtual Simulation

The use of digital twins allows companies to create virtual replicas of products and machines, enabling real-time monitoring and predictive maintenance.

This technology reduces downtime, increases efficiency, and lowers overall maintenance costs.

Advances in AI and Machine Learning

AI and machine learning algorithms are optimizing production lines by identifying inefficiencies and predicting maintenance needs.

These technologies are transforming traditional machine design into a more intelligent and adaptable process.

Conclusion: As industrial and machine design continue to evolve, manufacturing will become more efficient, sustainable, and adaptable. By adopting these cutting-edge technologies, companies can stay ahead of the curve and meet the changing demands of the global market.