How Industrial Design and Machine Design are Shaping the Future of Manufacturing

12 November 2024

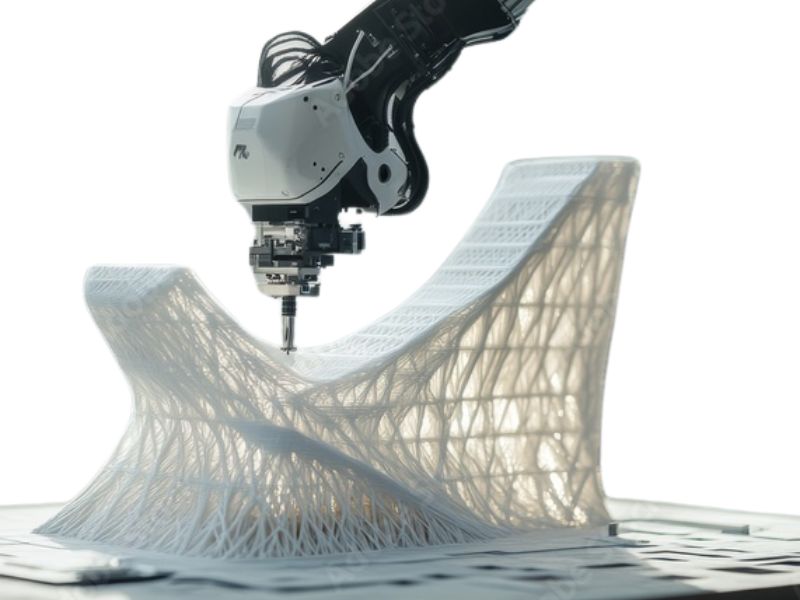

Introduction: 3D printing, or additive manufacturing, is transforming industries worldwide. From prototyping to final product manufacturing, 3D printing enables faster, cost-effective, and more sustainable manufacturing solutions. In this blog, we’ll dive into how 3D printing is revolutionizing industrial design and what benefits it brings to manufacturers.

Main Points:

Accelerated Prototyping

3D printing allows for rapid prototyping, making it easier to test designs before final production.

Designers can quickly iterate and refine prototypes, cutting down time from months to mere days.

Customization and Flexibility

With 3D printing, manufacturers can customize parts to meet specific client needs, increasing flexibility in the production process.

This is particularly valuable in industries like healthcare and automotive, where bespoke parts are essential.

Cost Reduction in Production

Traditional manufacturing can be costly due to setup, tooling, and waste. 3D printing reduces waste, which translates to lower costs.

The minimal need for expensive molds and tooling in 3D printing makes it accessible for smaller-scale production.

Environmental Benefits

3D printing is often a more sustainable option because it uses only the necessary materials, minimizing waste.

Many 3D printing materials can be recycled, and additive manufacturing is more energy-efficient than traditional methods.

Industry Applications and Future of 3D Printing

Highlight real-world applications in industries like automotive, aerospace, medical, and consumer products.

Predict future trends, such as increased material options and larger-scale industrial printers.

Conclusion: As 3D printing technology continues to advance, it will play a pivotal role in shaping the future of industrial design and manufacturing, offering endless possibilities for innovation and efficiency.